Food processing & internal transport

High demands are made of food processing. Not only during the production process itself, but also when it comes to the premises and the production environment.

The legal requirements are laid down in Regulation 852/2004. These principles form a common basis for the hygienic production of all foodstuffs. The aim of these hygiene regulations is to ensure food safety.

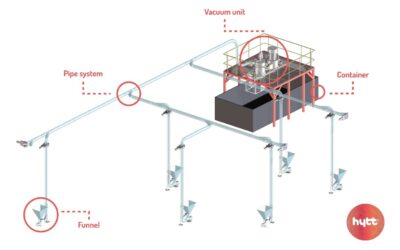

With the help of vacuum transport it is possible to move waste, by-products, other product flows quickly and hygienically through a closed stainless steel tube. HYTT designs and makes these internal transport systems to measure for the food processing industry.

An efficient design and an effective self-developed ejector based on venturi effect make vacuum transport more hygienic, safer, space-saving and maintenance-friendly. A clean, safe and efficient production area is the result.

HYTT is aware of the requirements, trends and developments in the food processing industry and will be pleased to advise you on the possibilities of hygienic internal transport in your production process.

Hygienic vacuum transport system operating in Food Plant of the year 2022

HYTT had the pleasure of speaking with Eric Ebling, director of maintenance at Bell & Evans. Ebling has been with Bell & Evans for about 25 years and has a lot of experience in the poultry industry. Who is Bell &...

Always a clean and hygienic production environment

Always a clean production area Maintaining a hygienic production environment is essential in the food industry. Among other things to prevent cross contamination and to meet quality and HACCP requirements and standards such as...

How hygienic internal transport can contribute to achieve a food safety certificate

Food safety and HACCP If you are a company active in the food industry, you are legally obliged to comply with the established hygiene regulations according to the HACCP guidelines. But the food trade also imposes strict...

Quality and audits in the meat sector

Consumers pursue quality and look critically at the meat sector. All chain partners in the meat sector (from producer to retailer) have a responsibility to ensure that meat can actually be consumed safely. To be able to...

Preventing food recalls

In the food industry, it is essential to be able to safeguard the food quality at all times. E.g. in the Netherlands article 19 of the General Food Law (ALV) defines the responsibilities of food producers for the marketing of...

CIP cleaning procedures

CIP cleaning of transport pipes is very important, even when waste is transported. Waste tend to build up along the inside of pipes. Rinsing with water is a temporary solution. Pigs are sometimes used to clean these pipes....