Hygienic transportation

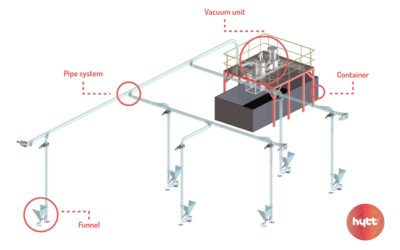

The hygienic transportation of food products is an important and difficult thing to manage. HYTT has put a lot of knowledge and energy in making an extremely hygienic transportation system. Due to the knowledge and passion of our employees, HYTT has committed itself in making a system that is as hygienic as possible.

The system is made of closed stainless steel pipes which sucks away waste or products from the production area. The waste or products are transported to a central point elsewhere in the facility. Because HYTT uses a closed piping system, there is a significant reduce in cross contamination risk.The system also significantly or completely removes manual internal transport. In addition to the advantage that this saves space, it also improves the overall hygiene because there is no more need for forklifts in the production areas. The HYTT system also makes workplaces cleaner by immediately sucking away the waste or product. This ensure that the workplace is cleaner, but also safer.

Because the HYTT system hygienically sucks the waste away, the waste can be converted into sellable products. This gives your business additional opportunities and profit. HYTT is specialized in specific solutions that are based on customer needs. For every internal transportation problem, there is a HYTT solution.Curious about how the HYTT system works? Would you like to know whether hygienic internal transport of waste and residual flows is possible in your production area? Read more

We would be happy to put our experience to work for you.

Turn your by-products from food production into greater profits

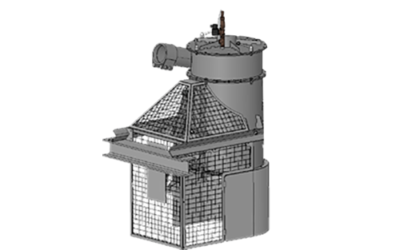

Upgrading by-product streams - mechanically separated meat In slaughterhouses or specialists in mechanically separated meat, the by-product stream can be upgraded by separating the bones from the meat. This is typically done by...

Installation advances hygienic and efficient transport of by-product and waste at Peoria Packing ltd.

Peoria Packing is an integrated family-owned company that started at the end of the 80’s and added in 1993 the Butcher shop in Chicago. “Some three years ago we broke ground for a new slaughterhouse to increase our capacity and...

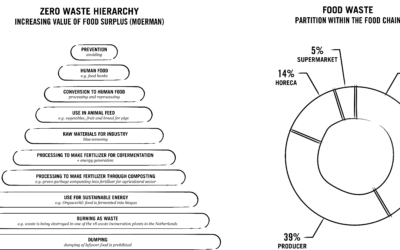

Preventing food loss, valorizing residual flows

Food is produced in a chain context and extends 'from farm to fork', from agriculture to consumption and the residual and waste processing of released food residues. Loss of the agricultural product occurs in all links of this...

Hygienic transportation

The hygienic transportation of products is an important and difficult thing to manage. HYTT has put a lot of knowledge and energy in making an extremely hygienic transportation system. Due to the knowledge and passion of our employees, HYTT has committed itself in making a system that is as hygienic as possible.

HYTT transport system, your hygienic internal transport solution!

A HYTT transport system, your internal transport solution! Internal transport is a difficult aspect to manage. When internal transport is not optimized, this will cost a lot of labour and money. Thanks to HYTT hygienic transport...

A HYTT System at Eisberg, Austria

A HYTT system at Eisberg, Austria At the end of March 2019, HYTT had the honour to be at opening ceremony of Eisberg for the world’s most modern processing plant for fresh convenience products, in Marchtrenk, Austria. At this...

Internal waste vacuum transport system for Oxfords Frozen Foods

A HYTT internal waste vacuum transport system for Oxfords Frozen Foods Within the next few weeks, HYTT will deliver a internal waste vacuum transport system for onion peelings. This fully vacuum system will be delivered to...

Animal by-products categories

What are animal by-products? Animal by-products, also know as ABPs, are materials of animal origin that people do not consume. ABPs include among others: Animal feed - e.g. based on fishmeal and processed animal protein Organic...

CE Certification

CE Certification of Hygienic Transport Systems Providing a CE certification on supplied equipment must be done in accordance with the law. Around our systems automatic movements of equipment will occur, this is PLC...